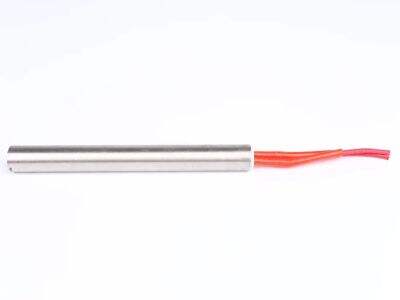

What is the most commonly used heating element in a wide-ranging of factories to help heat materials? Special tubes that heat up during the production. But some tubes do go wrong, and that isn’t no cakewalk to pick up. Overheating, tube breaking, short circuits and irregular heating are some common complaints.

If it becomes too hot, the tube will overheat and this can be dangerous and cause failure. Although drapery rods are designed to hold the weight of heavy window treatments a tube can easily be damaged if something heavy or hard happens to hit it. The electric circuit may give a short-circuit condition, if the connections with the inputs are not very good enough making system to get failed in working. Uneven heating may also occur due to temperature control malfunction. So parts of whatever you are heating will be either not hot enough or too hot.

Finding and Fixing Problems

If you want to get started with how the entire system works, this equation can help direct the search for Electric Heating Tube problems. Cons on the system is that it has several elements as for power — whatever heats up that tube, control parts—whatever tells how hot to heat the tube and sensors — whatever checks hose hot the temperature of heating regulator.

Power supply problems are some of the most common problems that people have with these tubes — if there is not enough power going to the tubes, they may flicker. Finally, heating materials can be damaged--the "element" is a metal material in the tube that heats the pump and the tube might not work as well. Temperature control failure: where sensors do not give the correct readings of temperature.

So if you are trying to figure out those problems, start by checking the power source so we could find out if it is in the right volts. But this is not enough, you must also ensure that the electricity which will be delivered through that digital socket is powerful enough to run properly. Then, take a good look at the heating materials to see if there are any signs of visible damage. Last but not the least check temperature sensors are working properly and giving accurate readings. If you identify any broken or unaligned components, they need fixed before your next ride or else a major mess could soon catch up with you.

Maintaining Proper Performance of Electric Heating Tubes

Periodic inspection, cleaning and maintenance should be performed to ensure that the electric heating tube operate normally. It serves to catch any potential problems early, preventing them from worsening and causing widespread destruction. The tubes need to be cleaned regularly, especially if dirt, dust, or any other debris has accumulated in them over time.

This is accompanied by a full visual inspection of the entire system for any external damage, signs of abnormal wear or tear, loose connections, and potential sources of system failure before it is equally lost. Along with cleaning and checking, monitoring temperatures through circuits, sensors and similar components can prevent tubes from working off their specs too early.

How to Troubleshoot Problems?

That said, you may implement some tips that could be of great help when dealing with heating tubes troubleshooting. One way is the performance of a visual inspection, i. e.: looking carefully inside the tubes with our eyes to check for mechanical damage or signs of wear (they have a limited operational run time). Circuit Testing – This is where you need to go measuring the power supply lines, and control circuits ensuring that they are good.

Sensors to temperature: Also, every unit can be equipped with a sensor and file allowing you to check that the sensors produce correct values. Combining these methods, a problem with the heating tubes can be determined and then addressed where keeping things smooth and running without an issue is necessary.

Ways to Prevent Problems

You can prevent the problems with electric heating tubes from occurring again by following these important measures. They include regular maintenance and inspection to locate problems before they can grow larger. Second, proper training is required for anyone who is going to be handling the heating tubes. This ranges from educating children on proper handling and necessary safety precautions.